Cassidy Atkinson and ARL Researchers investigate the effects of doping in silicon carbide grain boundaries. This research was supported by Dr. Sanjeev Nayak and Dr. Pamir Alpay. The work was published in Acta Materiala and can be accessed here.

Promise in Computational Chemistry Winner

Uchenna Anene won the “Promise in Computational Chemistry” award for speaking at the Women Make COMP symposium of the American Chemical Society, Fall 2021.

Women are under-represented in science and this symposium aimed to address this gender-gap by ensuring that young women in the field had the mentorship to pursue academia and industry fields.

Loading...

Loading...

MSE Alumna Serves U.S. Air Force as NRC Research Associate

UConn MSE alumna Tulsi Patel conducts her own research as an NRC Research Associate with the United States Air Force. Read the whole article.

UConn-Technion Collaboration Develops Model for Affordable Fuel Cell Catalysts

UConn researchers and collaborators at Technion – Israel Institute of Technology developed a theoretical model that will expediate the development of affordable fuel cells, a key technology for sustainable energy.

Radenka Maric, UConn’s vice president for research, innovation and entrepreneurship; Dario Dekel from Technion’s Chemical Engineering Department; S. Pamir Alpay, UConn’s associate dean for research and industrial partnerships; and Sanjubala Sahoo, a research scientist in Alpay’s group published their findings in ACS Catalysis in February.

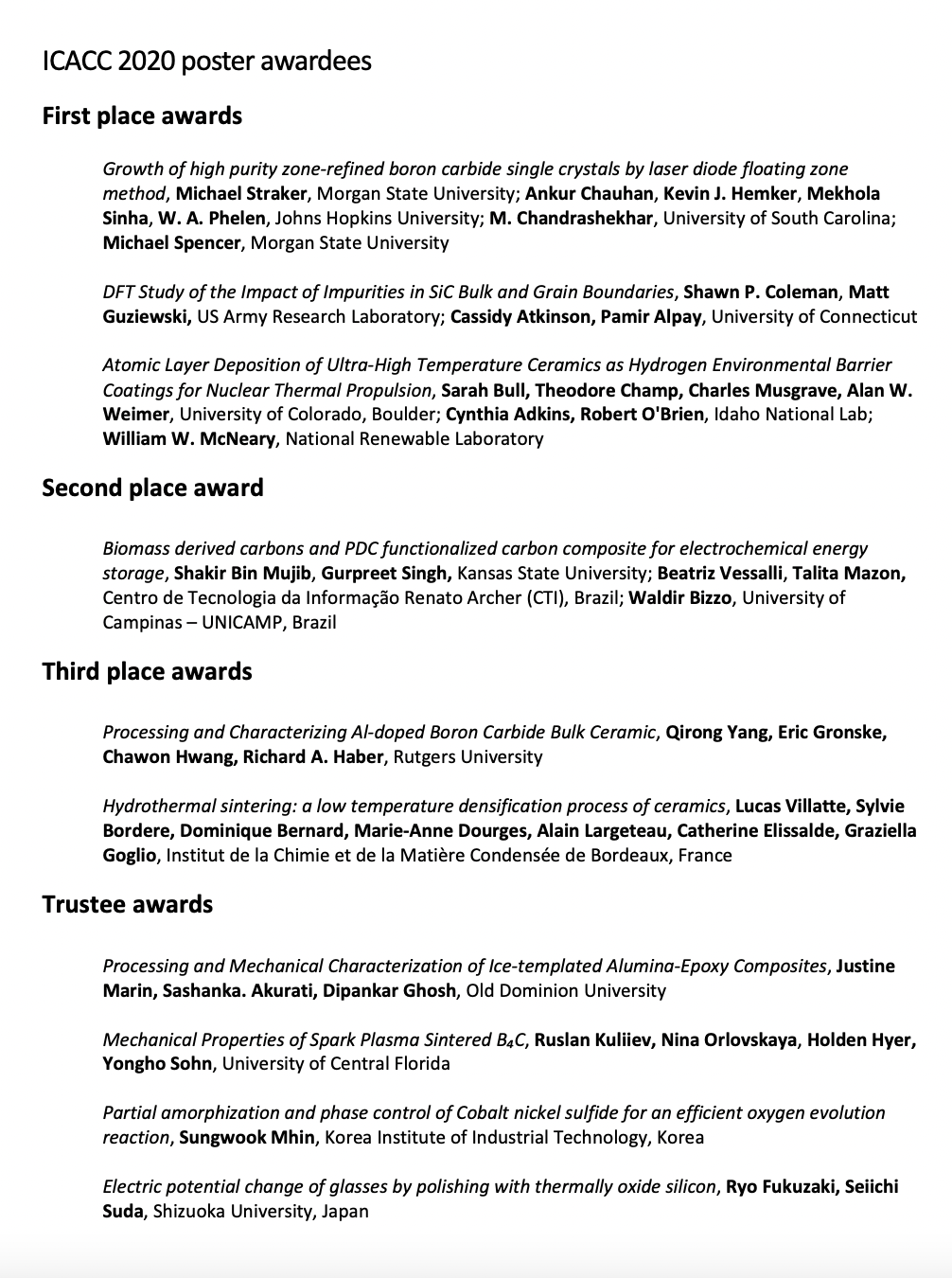

First Place Poster Award ICACC 2020

Sharon Uwanyuze Joins Research Group

MSE Professor Recognized as a Fellow of the Most Established Materials Information Society

December 30, 2020

Professor Alpay, Ph.D., has recently had the honor of being selected by the Board of Trustees of ASM International as a Fellow of the Society. This position recognizes his distinguished contributions in the field of materials science and engineering. It allows a broadly based forum for technical and professional leaders to serve as advisors to the Society. According to the Board, Alpay was elected for his “exceptional contributions and leadership in materials theory, computational materials science, and multi-scale materials modeling towards an understanding of aerospace alloys, functional materials, and surface properties.”

Read the full article here.

Army Research Laboratory Internship Later Influences Student’s Doctoral Dissertation Research

December 23, 2020

Cassidy Atkinson was highlighted in this article. Read it here.

UConn Receives $8 Million to Continue Air Force Research Lab Project in Advanced Manufacturing

September 1, 2020

The University of Connecticut has received an $8 million contract from the Air Force Research Laboratory (AFRL) to continue productive research aimed at improving aerospace manufacturing processes.

Read the full story here.

UConn, Army Research Lab Collaborate on New Portable, Renewable Energy Technology

June 17, 2020

UConn’s Associate Dean for Research and Industrial Partnerships, S. Pamir Alpay, and Yomery Espinal ’18 PhD (ENG) have published a paper on a novel portable pyroelectric technology in Cell Reports Physical Science with support from the Army Research Laboratory.

Read the full story here.